The bolt face design used by S&W in the 9mm Response is known to allow out-of-battery (OOB) discharges. Did they come up with a fix without changing the bolt face?

This information is intended solely for entertainment purposes only. Do not perform any action based on any of the following information. The accuracy of this information is not guaranteed or warranted. Always bring malfunctioning firearms to a qualified gunsmith for repair. All copyrights and trademarks are the property of their respective owners.

If you own a Smith & Wesson Response 9mm carbine and weren’t aware, there is a recall to fix potential OOB discharges.

Here’s one caught on camera (may take a moment to load):

This is no surprise to me, since I described this exact type of problem back in 2022. The root cause of the problem is the bolt face design. Their bolt lacks a bottom “feed” or “safety” lug that keeps the cartridge out in front of the bolt until it chambers. The bottom feed lug, combined with the extractor, keeps the firing pin from being able to hit the primer until after chambering.

Bolt WITH feed lug (left, green arrow). Bolt with MISSING feed lug (right, red arrow).

Why delete the feed/safety lug?

By excluding the bottom lug, the cartridge slides up under the extractor and is held in place, “controlled” by the bolt, as it travels toward the chamber. This supposedly gives better feed characteristics.

With the bottom feed lug in place, the cartridge “floats” forward loose, out in front of the bolt face. The bolt pushes the cartrige out in front, like a tugboat pushing a barge.

The problem:

Without the feed/safety lug, when the base of the cartridge slips up and under the extractor it is held tight against the bolt face. The firing pin is able to reach the primer before the cartridge is in the chamber. If anything stops the bolt before it fully chambers the cartridge (which was apparently the problem in the video above), and the hammer can reach the firing pin with enough force to ignite the primer, there can be an OOB discharge. This cannot happen with a bolt that has a feed lug (except under very, very extraordinary circumstances).

The S&W recall fix:

Based on the excellent before-and-after comparison video by Hollow Point Defense, we have a good idea of S&W’s approach to a solution. It reminds me of the way Colt solved one of the problems they had with their original 9mm design. It’s more of a “work around” than addressing the root cause. Even so, it’s a valid solution.

Back when Colt realized that their 9mm bolt was breaking bolt catches, one of their employees came up with a solution. Colt was using 3.25″ buffers, which was the normal carbine size. This was fine for the 5.56mm bolt carrier group, but was too short for the 3/4″ shorter 9mm bolt. The carbine buffer let the 3/4″ shorter 9mm bolt get “a running start” and smash the bolt catch during last round bolt hold open.

They presumeably had many of the 9mm carbine buffers already manufactured and in stock for installation in new guns. The employee suggested using a 4″ buffer. This would have required scrapping all their stock of 3.25″ buffers. Instead, they opted to put a 3/4″ aluminum spacer in the back of the buffer tube. That was a cheap “work around” fix for the problem and allowed them to keep using the 3.25″ buffers they already had. Now everyone uses 4″ buffers.

What does this have to do with S&W? Well, if they recalled, scrapped, and replaced the bolts, it would be VERY expensive, adding even more expense to a costly recall. So, it looks like they improvised a much less expensive work-around…

It appears that they reduced the amount of exposed firing pin sticking out the back of the firing pin channel. This sets the rear of the pin deeper in the bolt, and more flush, with the back of the firing pin channel. They also rounded the base of the pin a little. This makes it more difficult for the hammer to hit the base of the pin unless the bolt is closer to being fully in-battery. The hammer has to be more vertical to give a firm hit on the rear of the pin, meaning the bolt is more in-battery.

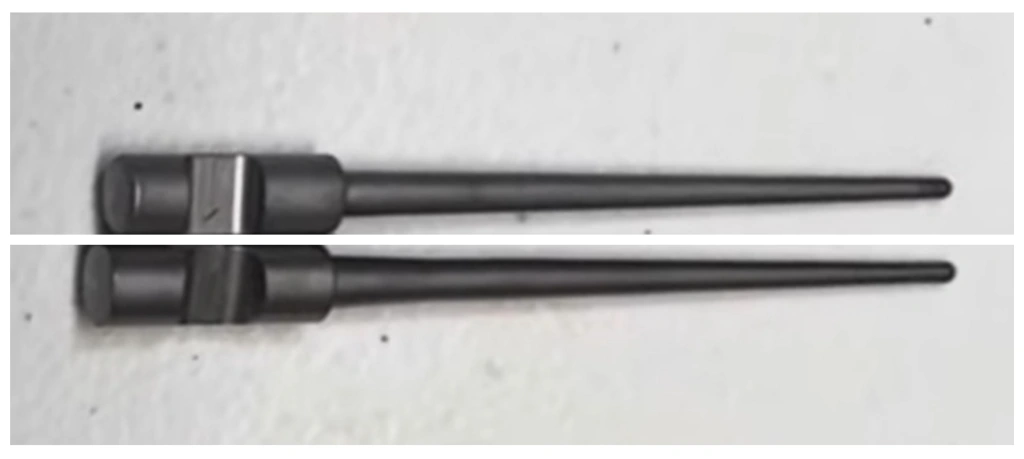

Here’s the same photo with the firing pin retaining groove and tips aligned. The “shortened” rear is now very clear. New on top, old on bottom:

To achieve this change, it appears they moved the firing pin retaining groove further back and reduced the overall length at the tip. This makes the rear of the pin harder for the hammer to hit if it’s out of battery.

This is what a normal firing pin looks like from the back when installed in a bolt:

You can see the base of a firing pin protruding from the rear of the firing pin channel. If the firing pin base is shorter and rounded, it’s harder for the hammer to hit the pin unless the bolt is further forward, and more fully in-battery.

It’s a simple work-around that should prevent the hammer from being able to hit the back of the firing pin with enough force to ignite the primer until the bolt is fully forward. Or, at least the bolt will have to be far enough forward that an unsupported cartridge base shouldn’t rupture. Instead, the bottom angle of the bolt should interfere with the hammer before it contacts the pin, slowing it enough to prevent primer ignition.

Will it work?

Time will tell, but this looks like it could be an effective work-around for the problem. This may allow the safe use of no-feed-lug “controlled feed” bolts.

My prediction: It will work, but it will result in more incidents of light-strikes and failures to fire (which is admittedly better than OOB discharges).

Key takeaway:

Manufacturing “controlled feed” bottom-lugless bolts requires more than just removing the lug from a current bolt design. Other design changes are necessary, such as reworking the firing pin, to help prevent OOB discharges.

Other changes to the S&W Response:

The changes to the firing pin were not the only changes S&W made to the recalled gun. Check the excellent comparison video by Hollow Point Defense to see all the changes/updates he found.