Flat wire recoil springs are quieter and provide more consistent spring pressure than a standard mil-spec recoil spring. I purchased 7 of the more popular AR flat wire recoil springs and compared them for buffer fit.

This information is intended solely for entertainment purposes only. Do not perform any action based on any of the following information. The accuracy of this information is not guaranteed or warranted. Always bring malfunctioning firearms to a qualified gunsmith for repair. All copyrights and trademarks are the property of their respective owners.

Flat wire springs are common in the recoil spring systems for semi-automatic pistols but not AR systems. They can compress into a smaller space and resonate less than round-wire springs. This makes them very desirable in the AR platform. Flat wire recoil springs effectively reduce or eliminate the annoying and distracting “sproingngngngngngng” noise that the AR is known for. They are a little more expensive, but not unreasonably so.

My primary interest in this topic is related to the “Gentle Recoil System“, which uses Kynshot hydraulic buffers, extra mass, and flat wire springs to significantly improve the shooting experience with 9mm AR’s.

Hydraulic buffer bodies are larger in diameter than normal buffers, and flat wire springs have smaller space in the inner diameter because of the width of the flat wire that makes up the spring. To get these two to work together better, I needed to find flat wire springs with sufficient inner diameter.

Another problem is the way many of the flat wire springs are terminated. The inner diameter of the end coil is often more narrow than the rest of the spring. This makes the buffer difficult to insert and snap into place, and the sharp edge often gouges the body of the buffer in the process.

The Contenders:

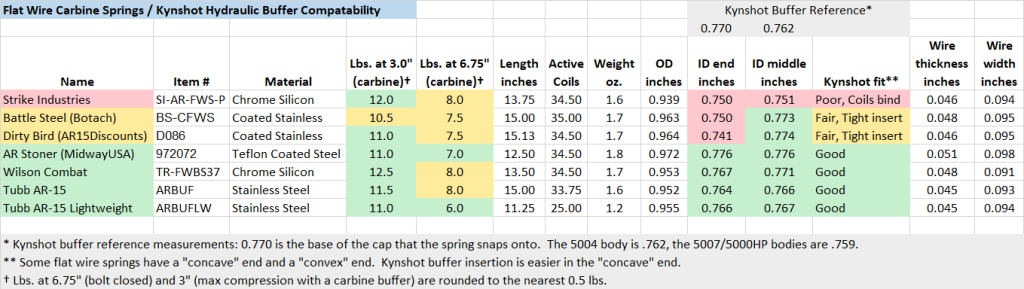

I purchased 7 of the more common flat wire springs, recorded all their measurements, and test fit them with my three Kynshot buffers and some other common buffers.

I don’t have an unlimited budget, so I tried to purchase a variety of budget and popular flat wire springs. From top down: 1) Strike Industries, 2) Battle Steel, 3) Dirty Bird, 4) AR Stoner, 5) Wilson Combat AR-15, 6) Tubb AR-15, 7) Tubb Lightweight/300BO

The Spring Tester Rig:

In order to measure the pressure applied by these springs, I needed a spring gauge. These are common for the much smaller 1911 recoil springs, but none exist commercially for AR-15 recoil springs. I’ve been using a scale and buffer tube up until now for testing AR recoil springs, but that’s less than ideal. I decided I finally had to break down and make one of my own design.

I used PVC to simulate a buffer tube, used a rod and washer down the middle as a plunger to pull the spring, got an Amazon digital hanging scale (tested, and it’s dead-on accurate), and used an old caulk gun as a come-along to pull the spring. This silly rig took me 6 Lowes trips, 3 build attempts, lots of leftover parts, and over 3 weeks of intermittent work to come up with a simple system that would produce repeatable, reliable results. A build list is provided at bottom of the page for anyone interested.

The first hole in the PVC indicates the 6.75″ compressed length, which is the bolt closed spring length in an AR. We’ll call this “L1″ for short. The second hole is for a 3” compressed length, which is the max compression with a carbine buffer at the end of the rearward bolt stroke. We’ll call this “L2”.

1911 springs are catageorized by “weight”, which is how much return force pressure they apply at fully slide-open position to push a cartridge into the chamber. If, at “fully open slide” the spring applies 14 lbs. of return force, it’s a “14 lb. spring.” A normal AR-15 round wire carbine spring per the mil-spec standard should have about L1 = 6.0 lbs. and L2 = 12 lbs. Per the 1911 nomenclature, this would be a “12 lb. spring”.

The mil-spec also specifies ± 1.0 lbs. at L2, so 11 to 13 lbs. is still considered in-spec.

The Measurements:

Here are all the measurements from the 7 flat wire springs. I had to calculate the inner diameter by subtracting 2x the spring width from the outer diameter, since the caliper jaws won’t fit in the middle of the spring.

(KAK Industries flatwire added under August 2023 update, below.)

Spring strength:

All of the springs were “in-spec.” for a standard military carbine compressed to fully-rearward position except for the Battle Steel. With 10.5 lbs. of force at the fully-rearward buffer position, this was below the military specifications. In live-fire tests it still seemed to work fine.

The minimum spring return force needed for a typical 9mm AR to function has not been determined. This will be a future experiment I’ll work on.

Buffer fit:

- My standard carbine buffers are 0.689″ – 0.702″ dia. The lip under the head is 0.782″.

- My extended buffers are 0.750″ – 0.752″ dia. The lip under the head (if present) is 0.782″.

- My Kynshot hydraulic buffers are 0.759″ – 0.762″ dia. The lip under the head is 0.769″

- A colleague measured their 5000 and 5000L Kynshot buffers and they were 0.759″ and 0.690″ dia.

The best buffer fit was from the Wilson Combat AR-15, the AR Stoner, the Tubb Lightweight, and Tubb AR-15 springs.

The Strike Industries, Battle Steel, and Dirty Bird springs either had difficulty fitting over the bodies of some of the buffers or were extremely difficult to snap over the wide lip under the head of the buffers. Although they will “work”, this is less than optimal, so they were eliminated from further consideration.

Bolt Slam Test:

Since I had not been able to get these out to the range right away, I installed each of the four springs in a 9mm AR with carbine buffer tube, locked the handle back, and listened/felt the behavior of each spring when I released the bolt on an empty chamber (with ear plugs). I repeated this action several times, going back and forth between the springs. This provided a decent comparison of the forward pressure on the bolt, muzzle dip, and the sound of the spring that a shooter would hear as the spring pushed the bolt into battery, without having to mentally filter out the report (the sound of the gunfire).

I know it wasn’t an optimal test, but it allowed me to compare the springs’ characteristics against one another.

Range Functionality Testing:

Nothing special to report. Every one of them worked just fine.

The Results (in order of current pricing):

In my opinion, any of these 4 springs should be a good choice for a blowback 9mm AR, especially one using a hydraulic buffer. None of them should be a “bad” choice. They should all fit on a hydraulic buffer, extended buffer, or carbine buffer without any issues. They should all have more than sufficient strength to operate a typical 9mm AR. As is standard, any new spring should be thoroughly live-fire tested in a setup before relying on it.

Wilson Combat AR-15: The Wilson Combat AR-15 flat wire spring measures as an 12.5 lb. spring, slightly stronger than a normal carbine spring, but not as strong as an “extra power” carbine spring. This extra pressure isn’t necessary at all for 9mm, but it’s the least expensive flat wire at $16 from MidwayUSA at the time of this writing, and in my opinion it’s the best value. It’s listed on MidwayUSA as stainless steel, but the Wilson Combat page lists it as chrome silicon.

Note: A reader has informed me that the AR-10 Wilson Combat flat wire spring is a poor choice for use with a hydraulic buffer. He reports it is much tighter and binds badly.

AR Stoner: The AR Stoner flat wire spring measures as an 11 lb. spring, applying a little less bolt return force than a normal carbine spring, but still “in-spec.”. At $20 it’s about 30% less expensive than the Tubb Lightweight, but it was just a little more noisy in the tube. It has a “teflon PVC” coating to help with friction. It’s a true coating on the wire, not a chemical treatment, so it will chip off. The type of steel they use is not listed. There was a noticable slight “twang” from the tube when running this spring during live fire testing.

This spring will help keep the bolt return stroke more gentle compared to a stronger spring, which should help improve the felt recoil experience in a 9mm AR.

Tubb Lightweight: The Tubb Lightweight spring, sometimes called the “Tubb 300 Blackout” spring, measures as an 11 lb. spring, and so is a little lighter than a standard mil-spec carbine AR spring, but still “in spec.”. This is the second most expensive spring I tested, costing $26, but it also gave the quietest forward stroke of the 4 “contenders” in the bolt slam test. This spring has already been tested by one of my readers with the full-weight Gentle Recoil System, and they report it works well in their setup.

This spring is designed for “lower pressure” cartridges like 300 Blackout and 300 Whisper, which in their subsonic form are essentially pistol cartridges with a spear point bullet. It appears to be a standard Tubb carbine spring minus about 8-9 coils. Both Tubb springs had a black coating that is flaking off and goes everywhere, so if you get one, lay out a newspaper/mat before working with them.

This was the quietest of all the springs. The other 3 made a little more noise in the tube than the Tubb Lightweight when returning to battery, but were still much quieter than a regular carbine spring.

Tubb AR-15: The Tubb AR-15 spring measures as an 11.5 lb. spring, very similar to a standard carbine spring, but is a little stronger at the bolt-closed position. At $28 each, this is the most expensive spring I tested. Tubb was a pioneer in promoting flat wire AR recoil springs, and has a good reputation, but their competition have caught on and are providing what appear to be similar products at significantly lower costs.

Links:

I do NOT get any kickbacks or revenue from these links. I have shopped at MidwayUSA and they often had the best prices I could find. Prices are as of 02/2023.

Wilson Combat AR-15 flat wire carbine $16 at MidwayUSA.com. $16 at Wilson Combat.

AR Stoner flat wire $20 at MidwayUSA.com.

David Tubb Lightweight carbine flat wire $26 at DavidTubb.com.

David Tubb standard AR-15 flat wire $27 at MidwayUSA.com. $28 at DavidTubb.com.

Dirty Bird carbine flat wire $23 at AR15Discounts.com. $25 at Dirty Bird Industries.

Battle Steel carbine flat wire $17 at Botach.com.

Strike Industries carbine flat wire $20 at MidwayUSA.com. $22 at Strike Industries.

Spring Tester Build List:

Parts list w/Lowes parts numbers where possible:

Tube, L to R:

– 2′ sch40 (1″ ID) PVC pipe (cut to 9″) 351142

– 1″ sch40 coupling 23852

– 1″ x 1/2″ bushing 23929

– 2 7/8″ screw eye bolt 64224

– 1/2″ sch40 adapter 23855 (larger end trimmed down to hex section)

Plunger, L to R:

– 1/4″ threaded rod (cut to about 13″) 215897

– 1/4″ lock nut 63403

– 1/4″ zinc washer 68882

– 3/8″ OD, 1/4″ ID PE tubing to cover the threaded rod and let it slide

– 1/4″ coupling nut 142056

– 1/4″ thumbscrew (wings trimmed to fit though 1/2″ PVC and drilled for S hook) 137368

Misc:

– S-hook

– URPRO Amazon hanging scale, oversized hook removed

– Thrift store $1 caulk gun

– Strip of felt for the scale to slide on

– 2 wood screws attaching the caulk gun to the end of the board (it had two holes already in the end cap)

– scrap 2×4 pallet wood

UPDATE: August 2023: KAK flatwire tested

Some folks asked if they should get the KAK flatwire carbine spring (instead of a Wilson Combat flatwire carbine spring) when getting the KAK Gold Top buffer, to save on shipping. So I bought one and tested it.

https://kakindustry.com/spring-m16-recoil-short-pistol-system-flatwire-17-7-no-finish

Manufacturer’s description:

Stainless steel flatwire buffer spring for KAK CQC buffer tube systems.

Works only with KAK Industry CQC buffer tubes and buffers. [editor note: also works with other KAK buffers]

Will not work with any other buffer system.

Spring characteristics:

26 active coils

12-3/8″ long

.945 OD

.095 wire width

.755 ID (calculated)

12.5 lbs at bolt open

7.5 lbs at bolt closed

Buffer fit:

Hydraulic 9mm/HD/HP buffers: Binds

Macon Extended 9mm deadblow: Binds

AR Stoner 11oz. Extended 9mm deadblow: Binds

Carbine 9mm solid: Tight

Hydraulic AR-15 (RB5000): Fits

Standard AR-15 carbine: Fits

KAK 10oz. Extended 9mm deadblow: Fits, but rubs.

Overall:

Not recommended for 9mm/HD hydrauilc, or 9mm extended/carbine buffers (other than KAK Industry brand – see below). The ID is a little too small and binds on the wider buffer body. May work with lots of lubrication on the buffer body and spring, but I wouldn’t risk it. Very unfortunate, because the spring characteristics seem very good but it’s just too snug on many buffers. I think KAK missed a big opportunity with this spring.

KAK chimed in on Reddit and let us know that their spring is designed to fit their buffers, which all follow the AR technical data package (TDP) for outer diameter. I can confirm it does fit their 10oz., but just barely. It rubs on the body and will wear the surface coating. So, it will work with their 8.4oz. gold top, 10oz. heavy, and K-SPEC PCC buffers, but may not fit buffers from other manufacturers. If there’s any chance you may use a 9mm buffer from another maker, it may not be the best choice.